JUHUA STEEL - Your Premier Partner for Precision Steel Solutions .

PRODUCTS

PRODUCT

Your Premier Partner for Precision Steel Solutions

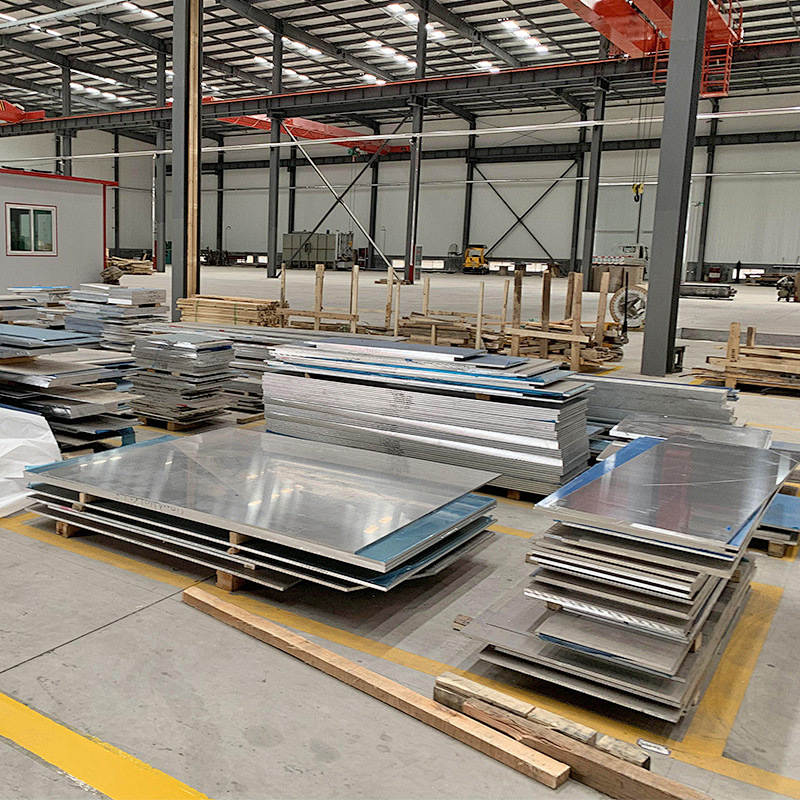

JUHUA, as a comprehensive steel service provider with annual sales exceeding 100,000 tons, boasts a full-range product matrix and modern production bases. Leveraging intelligent production lines and core surface treatment technologies.

We offer a diverse portfolio including stainless steel coils/sheets, galvanized coils/sheets, cold-rolled coils/sheets, aluminum-coated coils/sheets, color-coated coils/sheets, color roofing sheets, construction steel materials, drainage systems, and more. We are committed to delivering one-stop services for global clients—from material selection and customization to processing and distribution—addressing differentiated needs through our multi-product solutions.

Any Questions? Get In Touch.

We Can Recommend Suitable Products According To Your Needs.

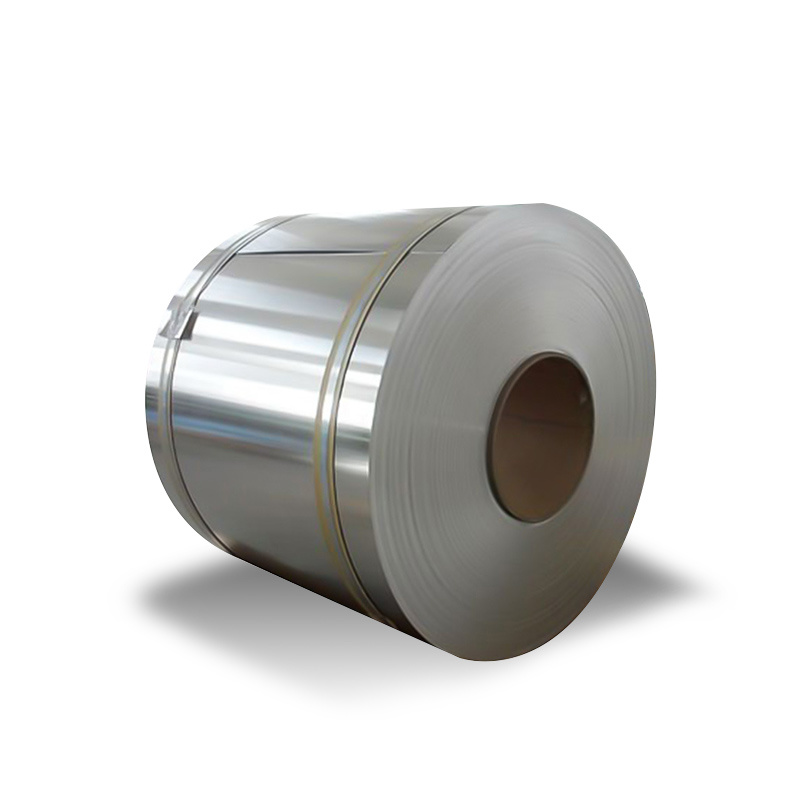

200 Series Stainless Steel: Contains lower chromium and nickel content, resulting in reduced material costs. While it offers moderate corrosion resistance (inferior to 300 series), this grade demonstrates higher mechanical strength and good workability. It is particularly suitable for cost-sensitive applications with moderate corrosion requirements, such as architectural decoration and kitchenware components.

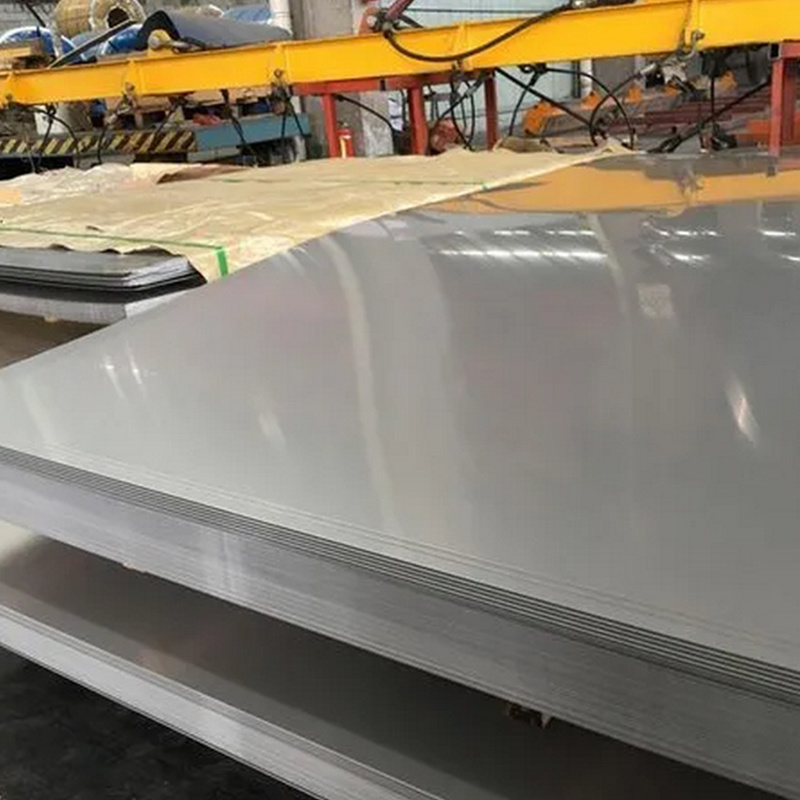

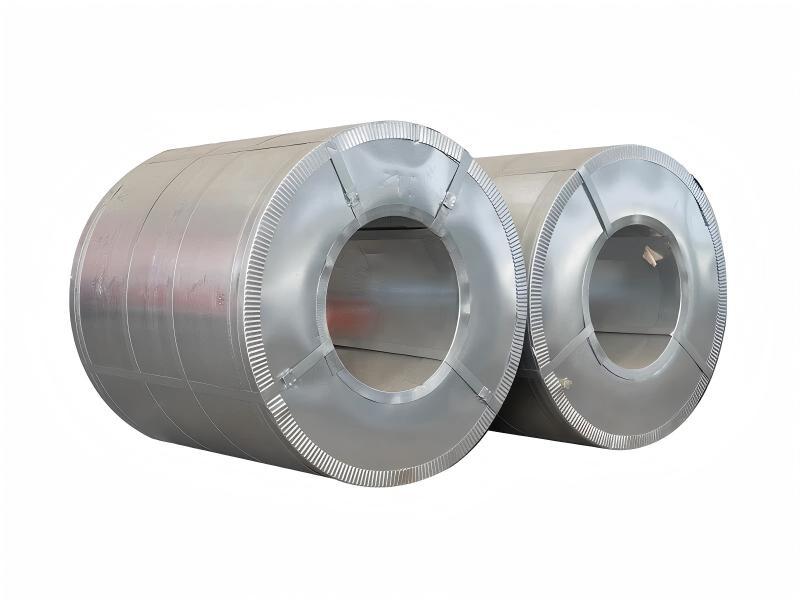

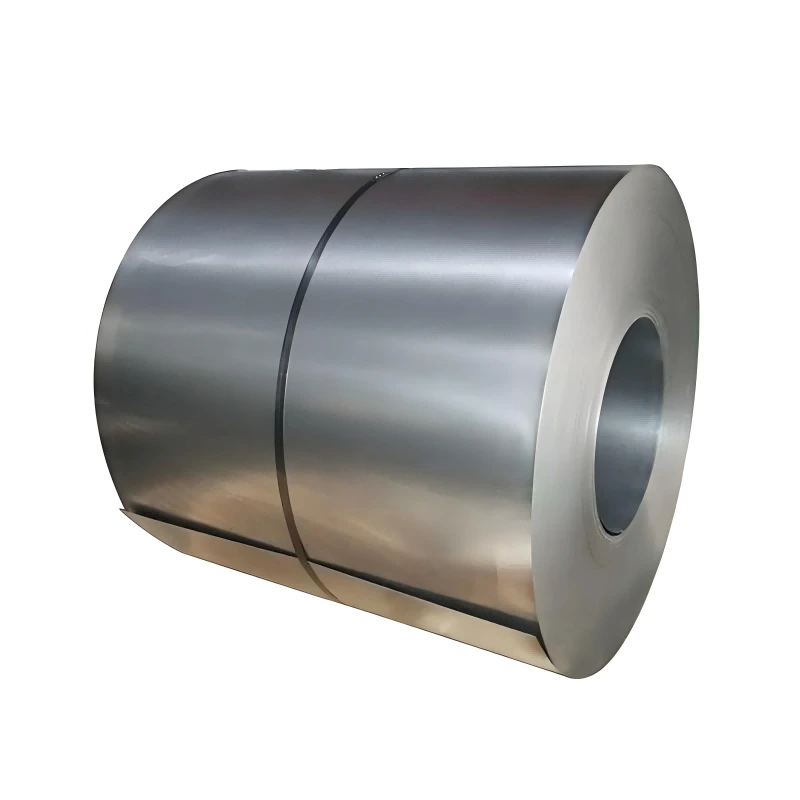

DX53D/DC53D/SGCE Galvanized Sheet

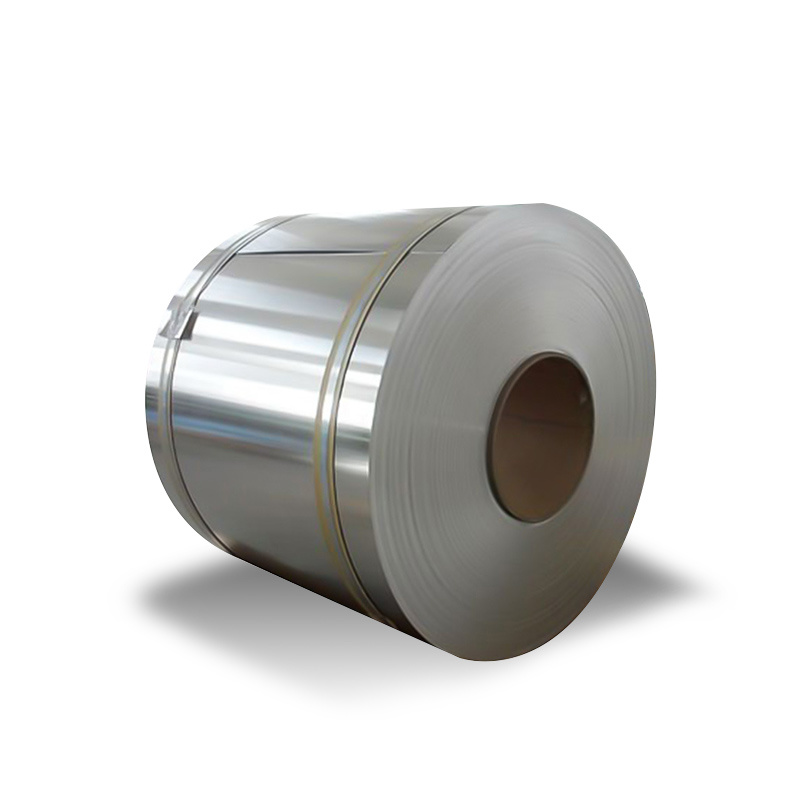

Hot-dip galvanized steel sheet is produced by immersing thin steel plates into a molten zinc bath to form a zinc coating on the surface. It is primarily manufactured through a continuous galvanizing process, where coiled steel strips are sequentially dipped in a zinc-rich plating bath. This type of steel sheet offers exceptional rust resistance, an aesthetically pleasing appearance, and excellent workability, making it widely applicable in construction, automotive, and home appliance industries.

DX51D/DC51D/SGCC Galvanized Sheet

Hot-dip galvanized steel sheet is produced by immersing thin steel plates into a molten zinc bath to form a zinc coating on the surface. It is primarily manufactured through a continuous galvanizing process, where coiled steel strips are sequentially dipped in a zinc-rich plating bath. This type of steel sheet offers exceptional rust resistance, an aesthetically pleasing appearance, and excellent workability, making it widely applicable in construction, automotive, and home appliance industries.

Galvanized Color-Coated Cold-Rolled Steel Sheet is manufactured by applying a zinc coating and subsequent color coating onto cold-rolled steel substrates. This composite material combines the high strength of cold-rolled steel, the rust-proof properties of galvanized layer, and the vibrant colors with enhanced corrosion resistance of color coating. Characterized by excellent workability, attractive appearance and superior durability, it finds extensive applications in construction, home appliances, and decorative fields.

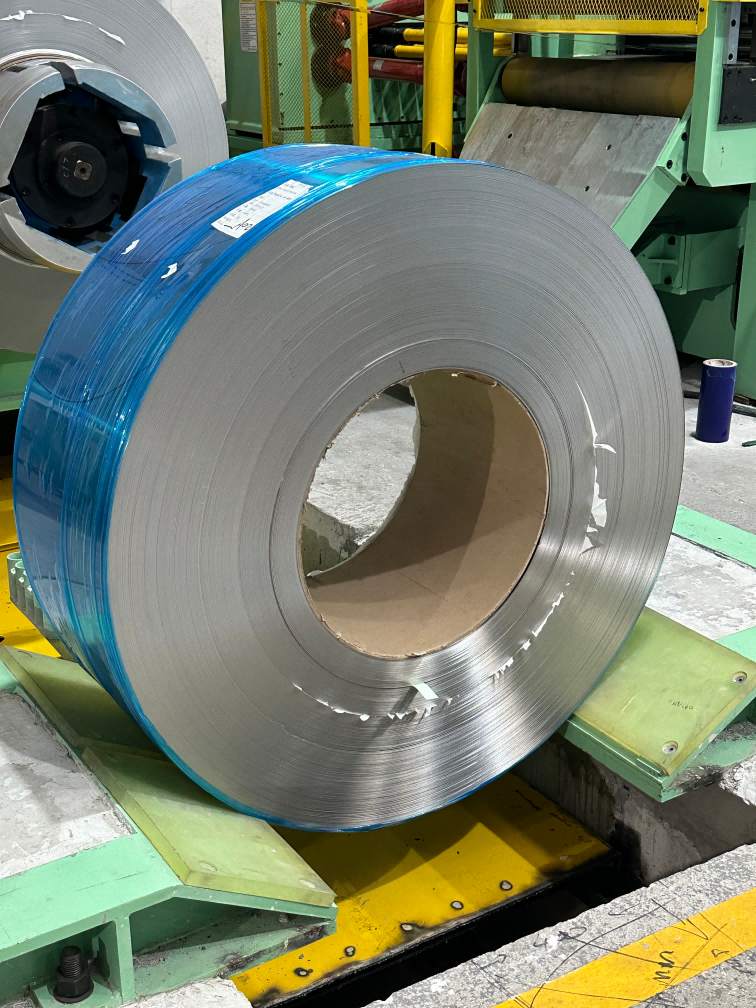

300 Series Stainless Steel: Represented by grades such as 304 and 316, this series features high chromium and nickel content. It delivers exceptional corrosion resistance, maintaining stability in acidic, alkaline, and other corrosive environments. With superior toughness and weldability, it is widely used in food processing equipment, medical devices, and chemical industrial applications, making it one of the most extensively utilized stainless steel series globally.

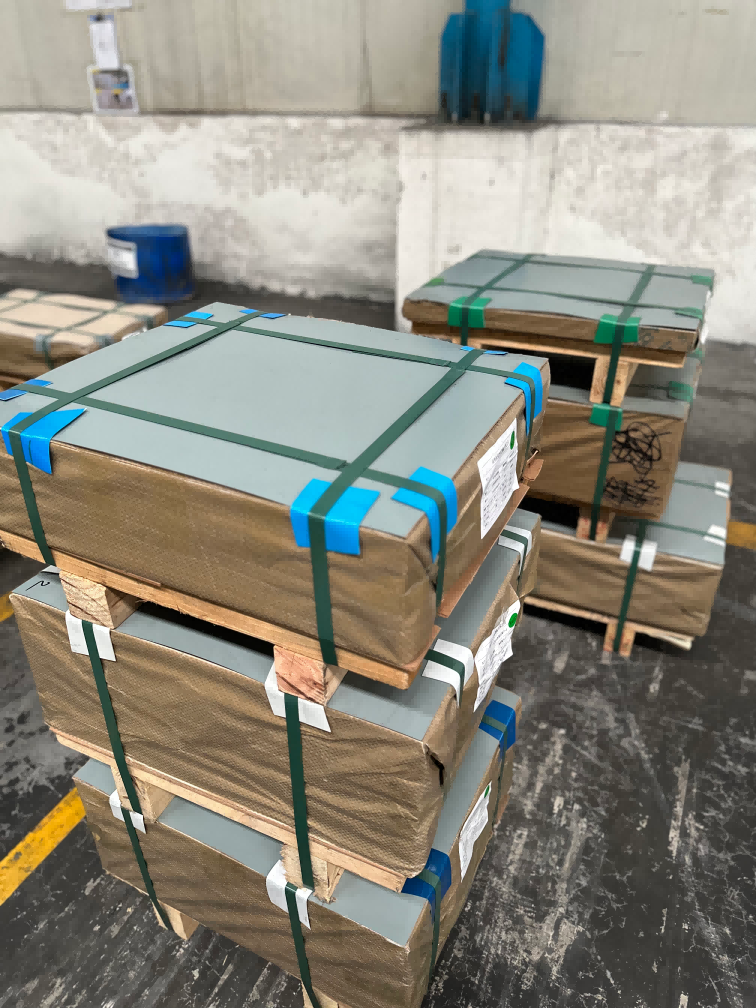

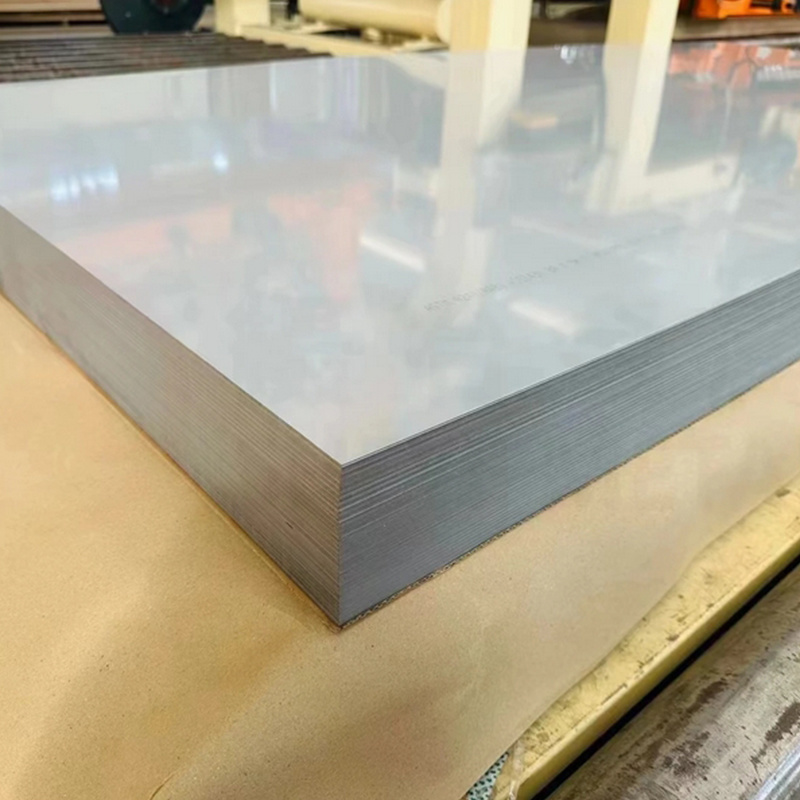

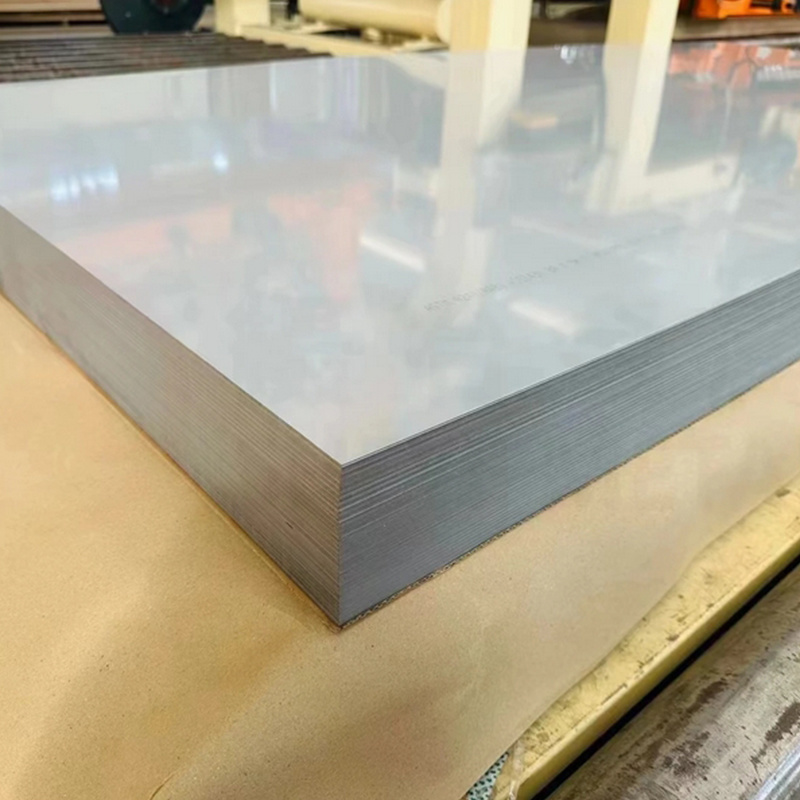

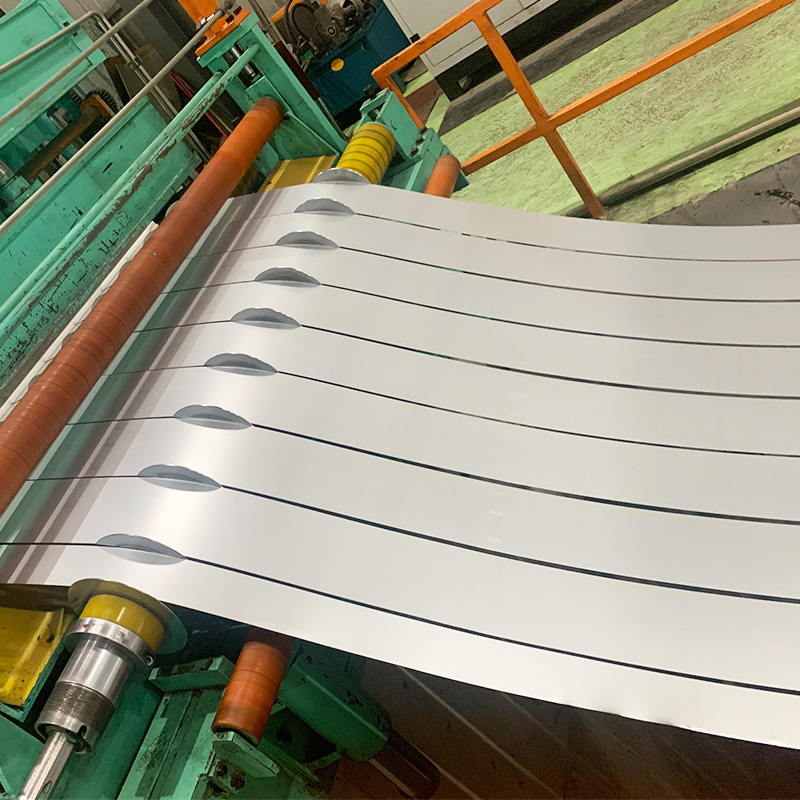

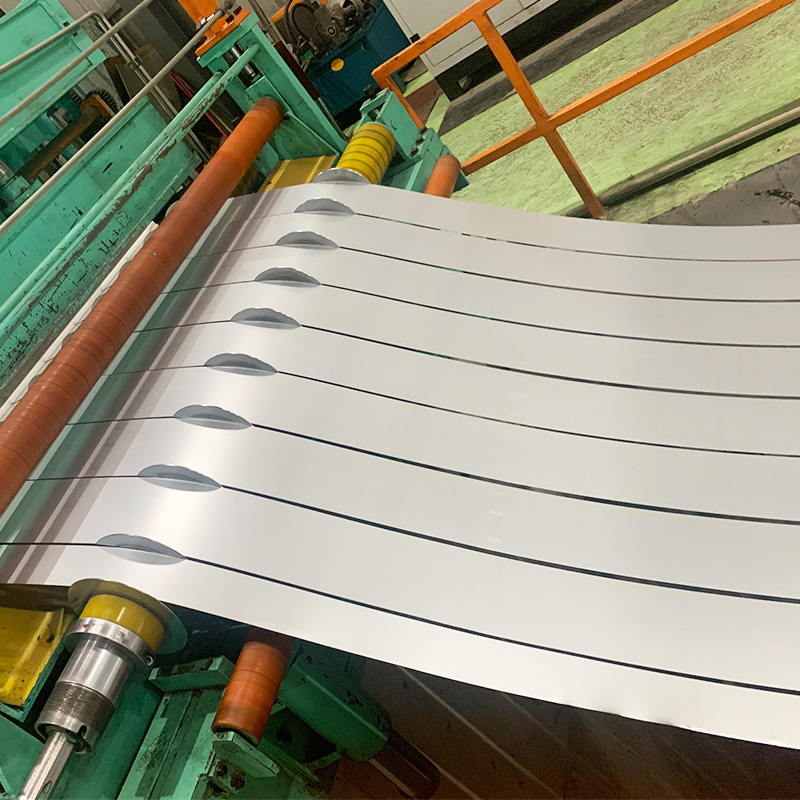

SPCC/DC01/ST12 Cold Rolled Sheet

Cold-rolled steel sheet is a type of steel plate processed through cold rolling, offering excellent toughness, ductility, and superior surface quality. It is particularly suitable for deep drawing and stamping processes, making it ideal for manufacturing complex components such as automotive body panels and appliance housings. With its high strength and outstanding formability, this material finds wide-ranging applications across multiple industries.

SPCE/DC04/ST14 Cold Rolled Sheet

Cold-rolled steel sheet is a type of steel plate processed through cold rolling, offering excellent toughness, ductility, and superior surface quality. It is particularly suitable for deep drawing and stamping processes, making it ideal for manufacturing complex components such as automotive body panels and appliance housings. With its high strength and outstanding formability, this material finds wide-ranging applications across multiple industries.

Aluminized steel is a kind of carbon steel treated by a hot-dip coating process on both sides with aluminum or aluminum-silicon alloy. This process aims to enhance its properties, particularly corrosion and rust resistance. Aluminized steel possesses the strength, hardness, and excellent mechanical properties of traditional steel while incorporating the attractive appearance of aluminum and its antioxidant properties. The perfect combination of these qualities makes aluminized steel a metal material with enhanced capabilities and wider applications.

Aluminized steel is a kind of carbon steel treated by a hot-dip coating process on both sides with aluminum or aluminum-silicon alloy. This process aims to enhance its properties, particularly corrosion and rust resistance. Aluminized steel possesses the strength, hardness, and excellent mechanical properties of traditional steel while incorporating the attractive appearance of aluminum and its antioxidant properties. The perfect combination of these qualities makes aluminized steel a metal material with enhanced capabilities and wider applications.

400 Series Stainless Steel: Represented by grades such as 410 and 430, this series contains high chromium content (typically 11-18%) with little to no nickel. It offers enhanced strength and hardness, along with excellent wear resistance. While its corrosion resistance is moderate compared to the 300 series, it performs exceptionally well in high-temperature and dry environments. Commonly used in automotive components, cutlery, and industrial blades, this series provides a cost-effective alternative to nickel-rich stainless steels.

400 Series Stainless Steel: Represented by grades such as 410 and 430, this series contains high chromium content (typically 11-18%) with little to no nickel. It offers enhanced strength and hardness, along with excellent wear resistance. While its corrosion resistance is moderate compared to the 300 series, it performs exceptionally well in high-temperature and dry environments. Commonly used in automotive components, cutlery, and industrial blades, this series provides a cost-effective alternative to nickel-rich stainless steels.

300 Series Stainless Steel: Represented by grades such as 304 and 316, this series features high chromium and nickel content. It delivers exceptional corrosion resistance, maintaining stability in acidic, alkaline, and other corrosive environments. With superior toughness and weldability, it is widely used in food processing equipment, medical devices, and chemical industrial applications, making it one of the most extensively utilized stainless steel series globally.