JUHUA STEEL - Your Premier Partner for Precision Steel Solutions .

The Ultimate Guide to Installing PCM Color Coated Steel: Best Practices for a Flawless Finish

Nov 07,2025

The Ultimate Guide to Installing PCM Color Coated Steel: Best Practices for a Flawless Finish

In the world of construction and architectural design, the choice of materials can significantly influence the overall outcome of a project. One material that has gained immense popularity due to its durability, aesthetic appeal, and cost-effectiveness is PCM (Polymer Coated Metal) color coated steel. This article delves into the best practices for installing PCM color coated steel, ensuring that you achieve a flawless finish while maximizing the longevity and performance of the material.

Table of Contents

- Understanding PCM Color Coated Steel

- Benefits of PCM Color Coated Steel

- Pre-Installation Preparations

- Tools and Materials Needed

- Installation Techniques

- Safety Measures During Installation

- Maintenance Tips for PCM Color Coated Steel

- Frequently Asked Questions

- Conclusion

Understanding PCM Color Coated Steel

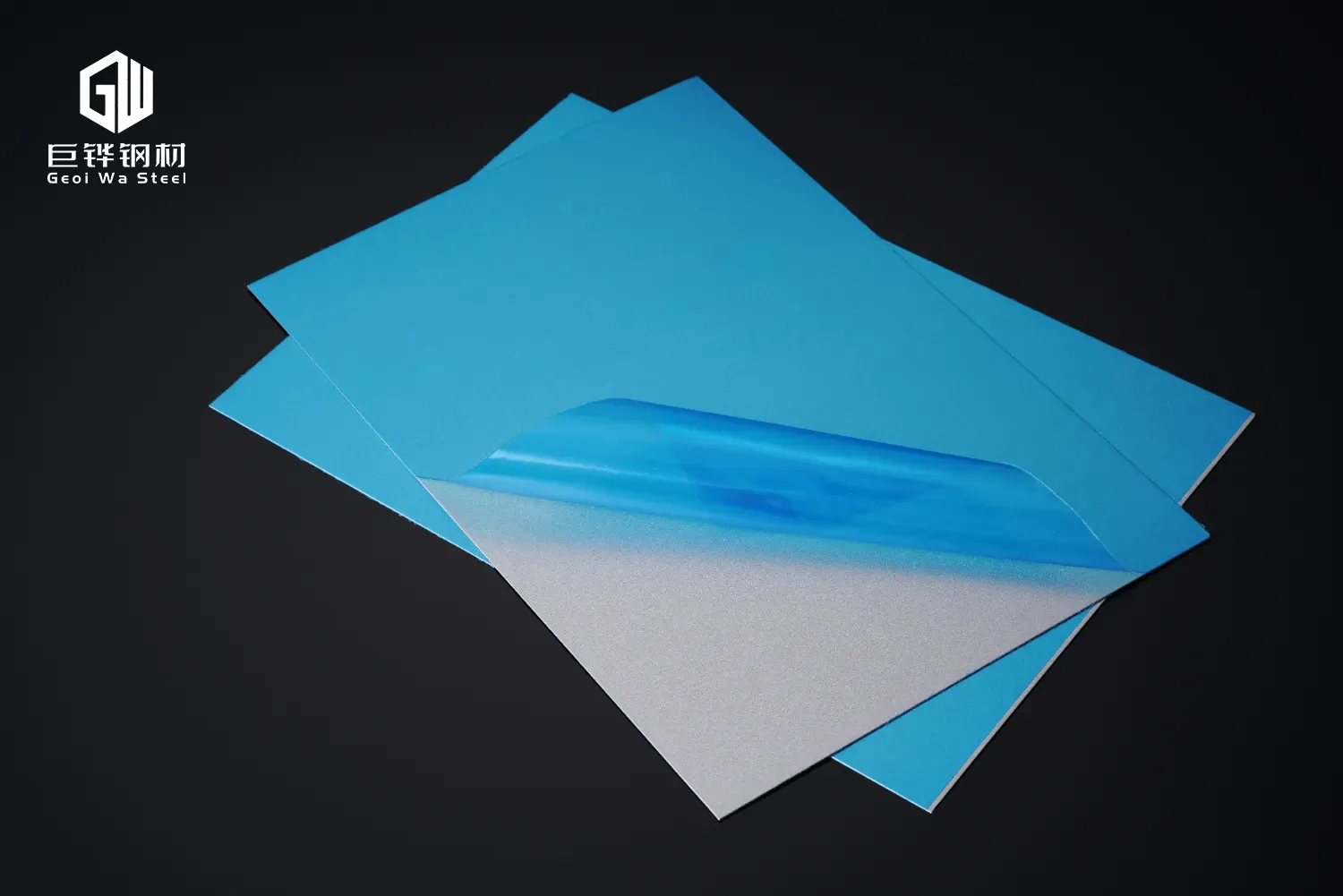

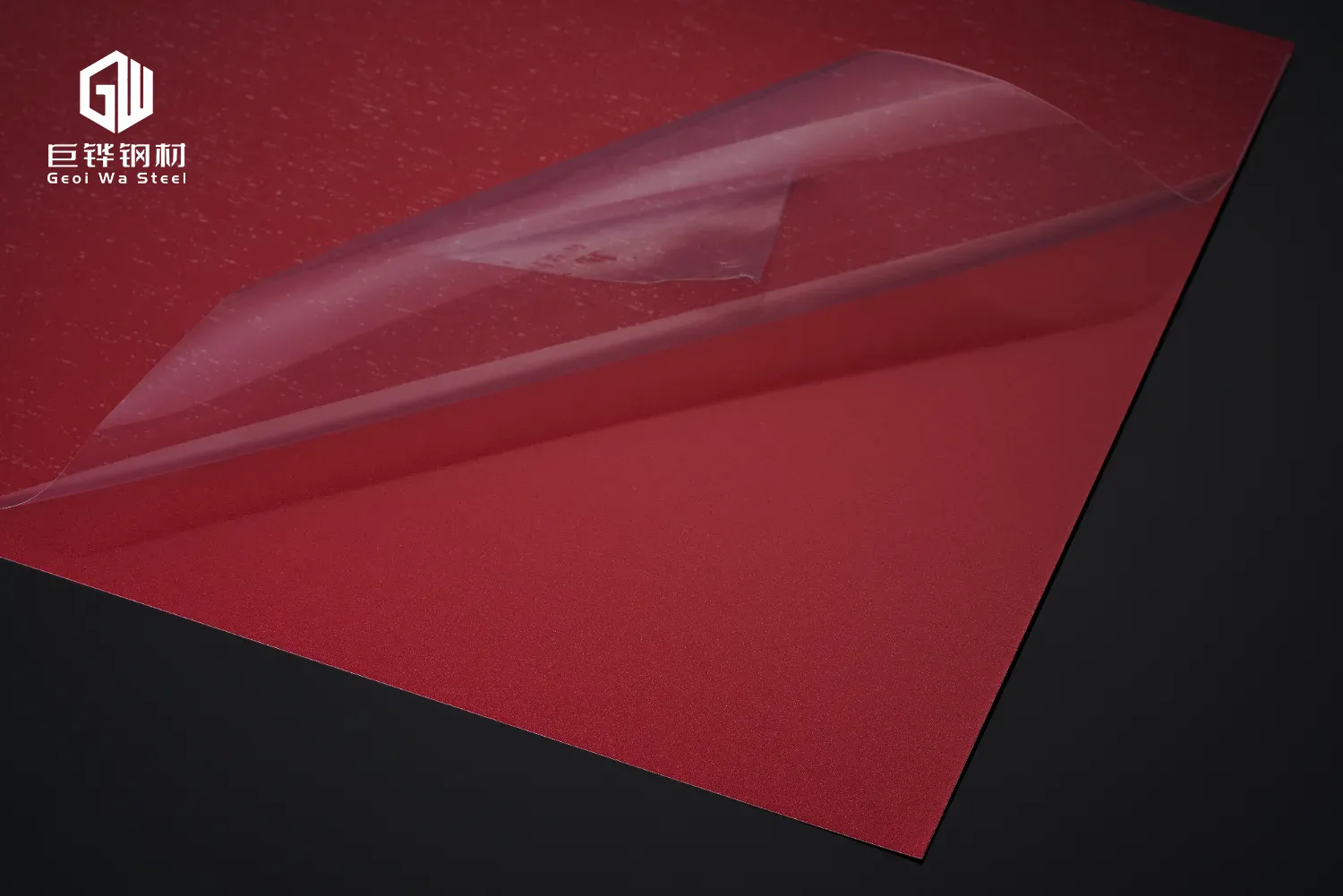

PCM color coated steel is a type of steel that has been coated with a layer of polymer to enhance its durability and aesthetic appeal. The polymer coating provides a barrier against rust, corrosion, and UV degradation, making it suitable for a variety of applications, from roofing to wall cladding. Understanding the composition and properties of PCM is crucial for its effective installation.

Composition of PCM Color Coated Steel

The base material of PCM color coated steel is typically galvanized steel, which is coated with a layer of zinc to prevent corrosion. Following the galvanization process, a polymer layer is applied, which not only adds color but also enhances the resistance to environmental factors.

Common Applications

PCM color coated steel is widely used in both residential and commercial projects. Common applications include:

- Roofing systems

- Wall cladding

- Industrial sheds

- Architectural facades

- Storage facilities

Benefits of PCM Color Coated Steel

Choosing PCM color coated steel for your projects offers numerous advantages:

Durability and Longevity

The polymer coating significantly increases the lifespan of the steel, offering protection against harsh weather conditions, UV radiation, and chemical exposure. This ensures that your investment lasts for years without requiring extensive maintenance.

Aesthetic Versatility

PCM color coated steel is available in a wide range of colors and finishes, allowing architects and designers to create visually appealing structures. The color retention properties of the polymer coating mean that colors remain vibrant over time.

Cost-Effectiveness

Due to its durability and low maintenance requirements, PCM color coated steel often proves to be more cost-effective in the long run compared to other materials. Additionally, its ease of installation can reduce labor costs significantly.

Pre-Installation Preparations

Proper preparations are vital for ensuring that the installation of PCM color coated steel goes smoothly. Here are some essential steps to follow:

Site Assessment

Before starting the installation, conduct a thorough site assessment. Check for any potential challenges, such as uneven surfaces, existing structures, or vegetation that may need to be cleared.

Measuring and Planning

Accurate measurements are crucial. Create detailed plans that outline the specific dimensions and layout of the PCM steel panels. This will help minimize wastage and ensure that all pieces fit correctly.

Permits and Regulations

Ensure that you have obtained all necessary permits and are compliant with local building codes. This step is essential to avoid delays and potential legal issues during and after installation.

Tools and Materials Needed

Having the right tools and materials on hand will streamline the installation process:

Essential Tools

- Measuring tape

- Level

- Circular saw with a metal cutting blade

- Power drill with metal drill bits

- Rivet gun

- Screwdriver

- Safety gear (gloves, goggles, helmet)

Materials

- PCM color coated steel panels

- Fasteners (screws, rivets)

- Sealants and adhesives

- Flashing and trims

Installation Techniques

Executing proper installation techniques is crucial for achieving a flawless finish. Follow these steps for successful installation:

Preparing the Surface

Ensure that the surface where the PCM color coated steel will be installed is clean, dry, and free of any debris. This will help the panels adhere better and ensure a longer lifespan.

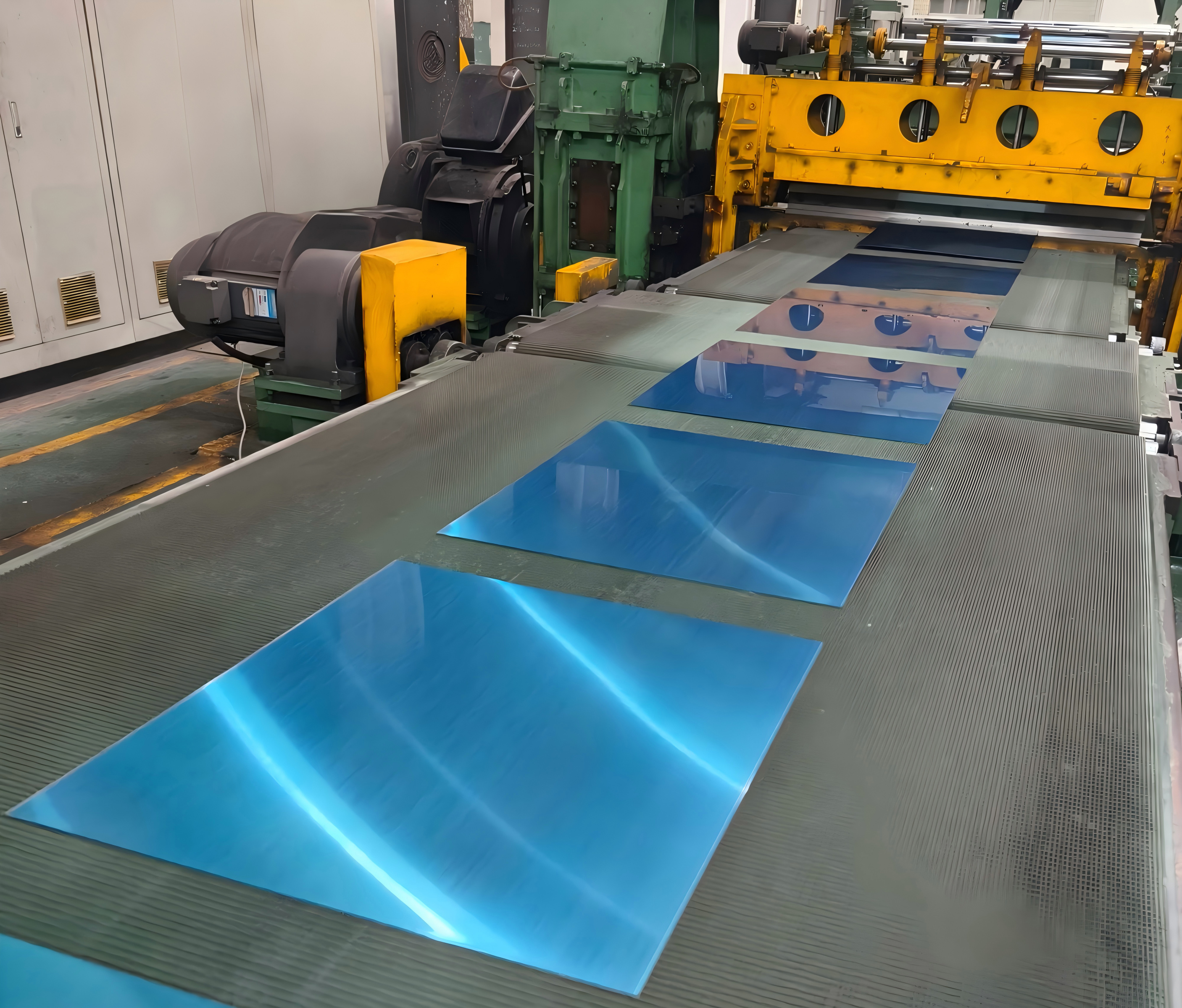

Panel Installation

Start by positioning the first panel. Use a level to ensure it is perfectly straight. Secure the panel using the appropriate fasteners, paying attention to the manufacturer's specifications for spacing and placement.

Sealing and Trimming

After installing the panels, use sealants to fill any gaps and ensure watertight integrity. Install trims and flashing around edges and joints to provide additional protection against weather elements.

Quality Control

Once the installation is complete, conduct a thorough inspection to check for any imperfections, loose panels, or areas that require additional sealing. Address any issues before considering the project finished.

Safety Measures During Installation

Safety should always be a top priority during installation. Here are essential safety measures to follow:

Personal Protective Equipment (PPE)

Ensure that all workers wear appropriate PPE, including gloves, helmets, goggles, and steel-toed boots. This helps minimize the risk of accidents and injuries.

Safe Handling of Materials

When handling PCM color coated steel panels, ensure that they are properly supported to prevent falling or causing injury. Use proper lifting techniques and team coordination when moving larger panels.

Fall Protection

If working at heights, implement fall protection measures such as harnesses and guardrails. This is crucial for safeguarding workers from accidents associated with falls.

Maintenance Tips for PCM Color Coated Steel

To maximize the lifespan of PCM color coated steel, regular maintenance is essential:

Regular Inspections

Schedule regular inspections to check for signs of wear, damage, or corrosion. Early detection can save time and money on repairs.

Cleaning

Clean the surface periodically using a soft cloth and mild detergent. Avoid using abrasive materials that can scratch or damage the polymer coating.

Addressing Damage

If any damage occurs, such as scratches or dents, address them promptly. Use touch-up paint or sealants specifically designed for PCM materials to restore integrity.

Frequently Asked Questions

1. What is PCM color coated steel?

PCM color coated steel is galvanized steel coated with a polymer layer to enhance durability, corrosion resistance, and aesthetic appeal.

2. How do I maintain PCM color coated steel?

Regular inspections, cleaning with mild detergent, and immediate repair of any damage are essential for maintaining PCM color coated steel.

3. Can PCM color coated steel be used for roofing?

Yes, PCM color coated steel is ideal for roofing due to its durability and resistance to environmental factors.

4. What are the benefits of using PCM color coated steel?

The benefits include durability, aesthetic versatility, and cost-effectiveness, making it a popular choice in construction.

5. How do I install PCM color coated steel correctly?

Follow proper installation techniques, including preparing the surface, securing panels properly, and ensuring watertight seals with trims and flashing.

Conclusion

Installing PCM color coated steel is a task that requires careful planning, the right tools, and adherence to best practices for a successful and durable outcome. By understanding the material's properties, following precise installation techniques, and implementing effective safety measures, you can ensure a flawless finish that not only enhances the aesthetic appeal of your project but also maximizes the material's longevity. With regular maintenance and inspections, PCM color coated steel can provide enduring performance, making it a wise investment for any construction or renovation project.

Latest News

2025-10-17

Any Questions? Get In Touch.

We Can Recommend Suitable Products According To Your Needs.