JUHUA STEEL - Your Premier Partner for Precision Steel Solutions .

The Future of Construction: Why Aluminized Steel is a Game Changer

Oct 22,2025

The Future of Construction: Why Aluminized Steel is a Game Changer

Table of Contents

- Introduction to Aluminized Steel

- What is Aluminized Steel?

- The Benefits of Aluminized Steel in Construction

- Applications of Aluminized Steel in Modern Construction

- Durability and Lifespan of Aluminized Steel

- Environmental Impact and Sustainability

- Cost-Effectiveness of Aluminized Steel

- Future Trends in Construction Materials

- Conclusion

- FAQs

Introduction to Aluminized Steel

In the realm of modern construction, the choice of materials can significantly influence the longevity, safety, and sustainability of buildings. One material that has gained considerable attention is aluminized steel. This innovative product combines the strength of steel with the corrosion resistance of aluminum, making it a formidable contender in the construction industry. In this article, we will explore the myriad reasons why aluminized steel is poised to revolutionize construction practices and set new benchmarks for performance and efficiency.

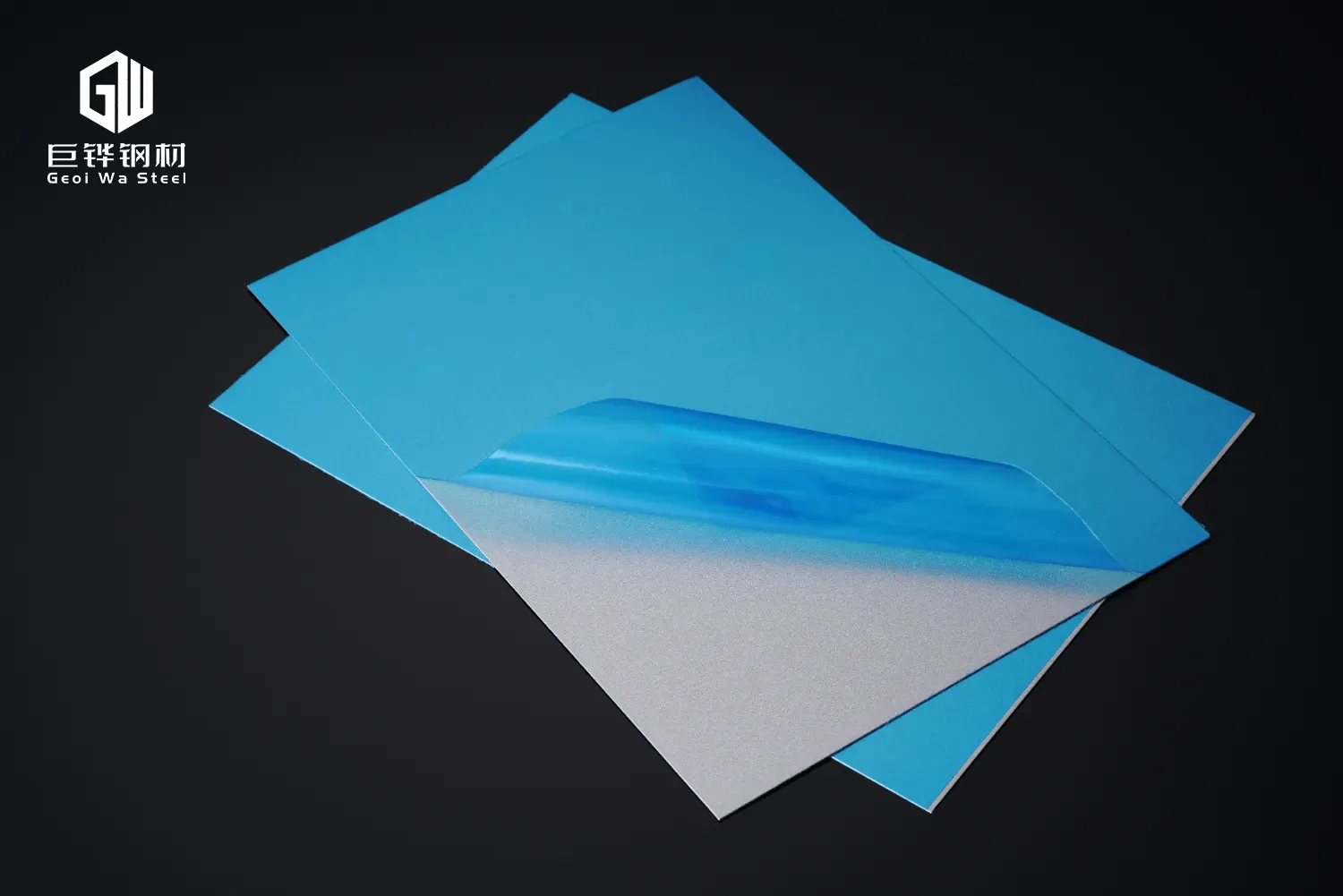

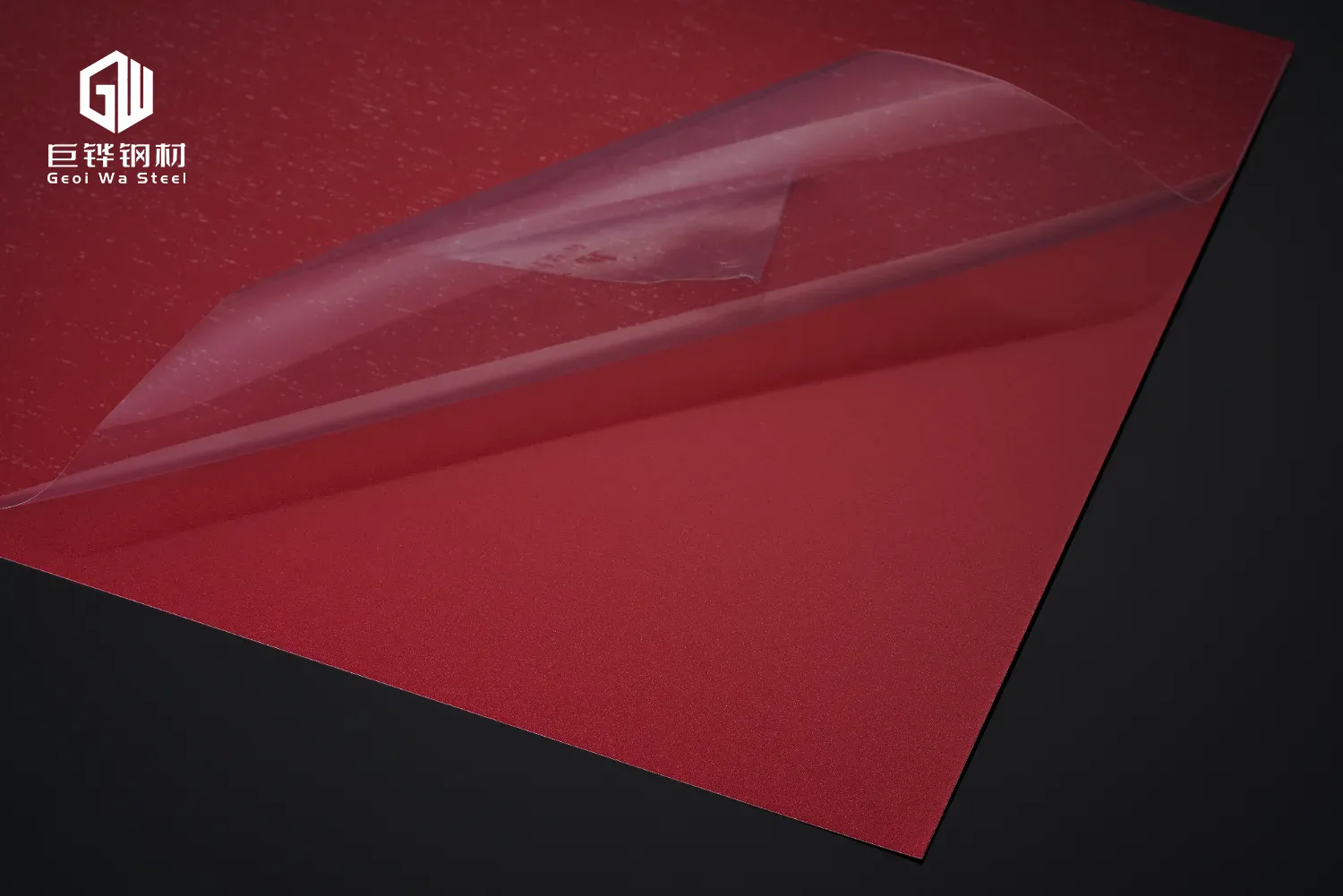

What is Aluminized Steel?

Aluminized steel is a type of steel that has been coated with an aluminum-silicon alloy. This process enhances the steel's resistance to corrosion and heat, providing an excellent barrier against the elements. The typical composition of aluminized steel includes 55% aluminum, 43.5% steel, and 1.5% silicon, creating a material that boasts the best of both worlds. This advanced coating process not only improves the durability of steel but also enhances its aesthetic appeal, making it a popular choice for various applications.

The Benefits of Aluminized Steel in Construction

Aluminized steel offers a range of benefits that make it an attractive option for construction projects:

1. Exceptional Corrosion Resistance

One of the standout features of aluminized steel is its resistance to corrosion. Unlike traditional steel, which can rust when exposed to moisture, aluminized steel forms a protective layer that prevents oxidation, thereby extending its lifespan significantly.

2. Heat Resistance

The aluminum coating on aluminized steel allows it to withstand high temperatures without degrading. This makes it suitable for applications where exposure to heat is a concern, such as in industrial settings or in the construction of buildings that require fire-resistant materials.

3. Lightweight yet Strong

Despite its robust nature, aluminized steel is lightweight, which can reduce the overall weight of a structure. This quality allows for easier handling and installation, as well as lower transportation costs.

4. Aesthetic Versatility

Aluminized steel has a shiny, metallic finish that enhances the visual appeal of buildings. Its aesthetic versatility makes it suitable for both modern and traditional architectural designs.

Applications of Aluminized Steel in Modern Construction

The versatile nature of aluminized steel allows it to be utilized across various construction applications:

1. Building Facades

Due to its corrosion resistance and aesthetic properties, aluminized steel is an ideal choice for building facades, offering both protection and beauty.

2. Roofing Materials

Aluminized steel is often used in roofing systems, providing durability and resistance to harsh weather conditions while reflecting sunlight, which can help regulate building temperatures.

3. HVAC Systems

In heating, ventilation, and air conditioning systems, aluminized steel is employed in ductwork and other components, where its heat resistance is particularly beneficial.

4. Automotive Applications

Beyond construction, aluminized steel is also making waves in the automotive industry, where it is used for exhaust systems and other components that require heat resistance and durability.

Durability and Lifespan of Aluminized Steel

The durability of aluminized steel is one of its most significant advantages. When compared to galvanized steel, aluminized steel exhibits superior resistance to corrosion in high-temperature environments. This resilience translates to a longer lifespan, making it a cost-effective choice for construction projects. In many cases, structures built with aluminized steel can last for decades, reducing the need for costly repairs or replacements.

Environmental Impact and Sustainability

Sustainability is an essential consideration in modern construction. Aluminized steel contributes to a more sustainable future through its longevity and recyclability. Because it lasts longer than traditional steel, projects that utilize aluminized steel require fewer resources over time. Additionally, aluminized steel can be recycled at the end of its life cycle, further minimizing its environmental footprint.

Cost-Effectiveness of Aluminized Steel

When evaluating the overall cost of construction materials, it is crucial to consider not just the initial purchase price but also the long-term savings associated with durability and maintenance. Although aluminized steel may have a higher upfront cost than some alternatives, its remarkable lifespan and low maintenance requirements make it a prudent investment. Projects utilizing aluminized steel can benefit from reduced operational costs, translating into significant savings over time.

Future Trends in Construction Materials

As the construction industry evolves, so too do the materials that shape it. The ongoing trend towards sustainability and resilience in construction materials is expected to propel the adoption of aluminized steel. Innovations in manufacturing processes and coatings may further enhance the properties of aluminized steel, paving the way for even broader applications. The construction industry will continue to explore materials that offer durability, cost-effectiveness, and environmental benefits, with aluminized steel leading the charge.

Conclusion

The future of construction is bright, and aluminized steel stands at the forefront of this revolution. With its unique combination of strength, durability, and aesthetic appeal, aluminized steel is uniquely positioned to meet the demands of modern construction. As we embrace sustainability and efficiency in building practices, aluminized steel is sure to play a pivotal role in shaping resilient and beautiful structures for generations to come.

FAQs

1. What makes aluminized steel different from galvanized steel?

Aluminized steel is coated with an aluminum-silicon alloy, providing superior heat resistance and corrosion protection compared to galvanized steel, which is coated with zinc.

2. Can aluminized steel be used in outdoor applications?

Yes, aluminized steel is highly resistant to corrosion and is suitable for various outdoor applications, including roofing and facades.

3. Is aluminized steel more expensive than regular steel?

While aluminized steel may have a higher initial cost, its durability and low maintenance needs can lead to overall cost savings in the long run.

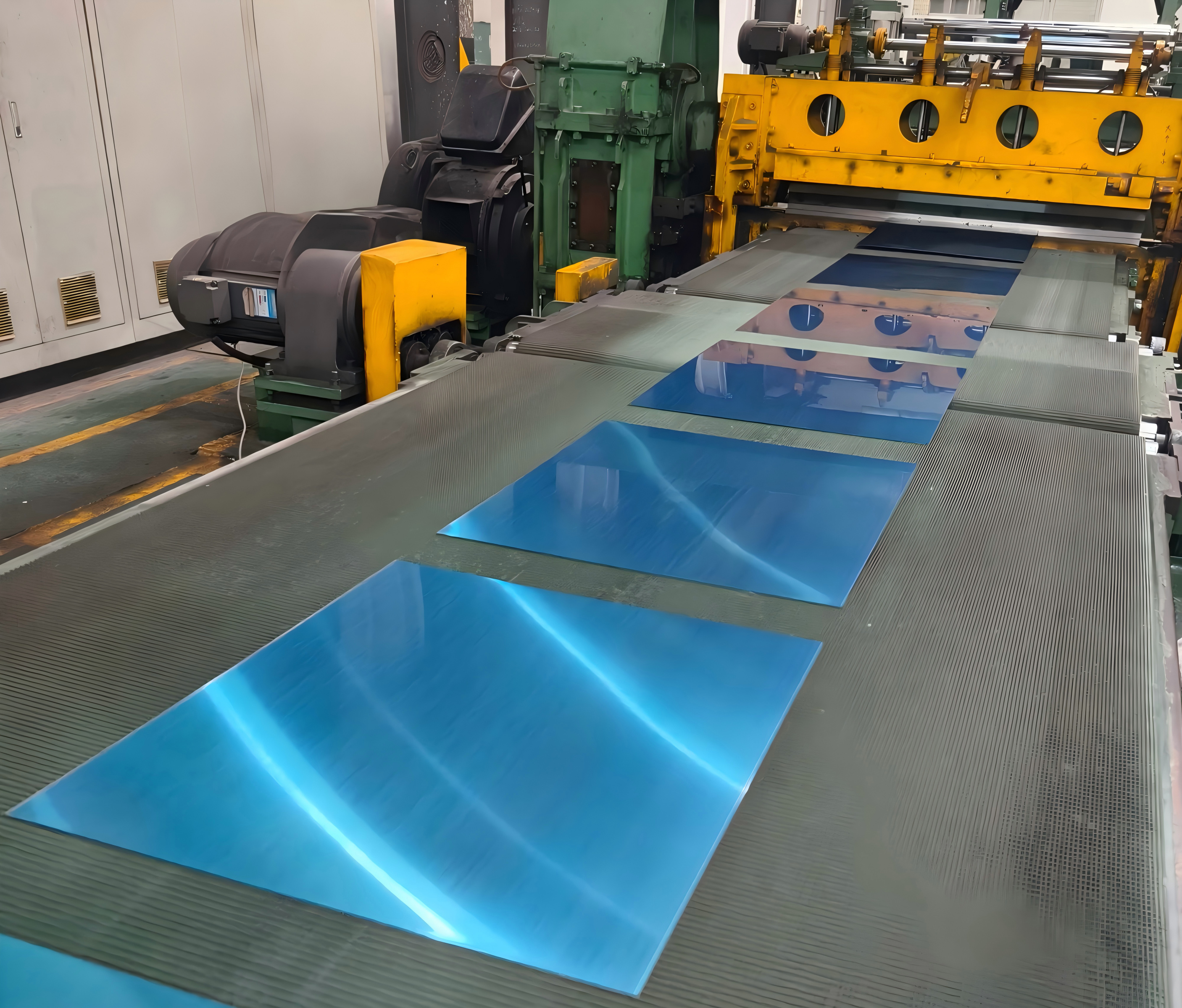

4. How is aluminized steel manufactured?

Aluminized steel is produced by continuously hot-dipping steel in a molten aluminum-silicon alloy, creating a strong and durable coating.

5. What industries utilize aluminized steel?

Aluminized steel is used in various industries, including construction, automotive, and HVAC, due to its strength, heat resistance, and aesthetic appeal.

PREVIOUS:

Latest News

2025-10-17

Any Questions? Get In Touch.

We Can Recommend Suitable Products According To Your Needs.