JUHUA STEEL - Your Premier Partner for Precision Steel Solutions .

Why 55% Aluminum Zinc Steel is the Future of Construction Materials

Oct 30,2025

Why 55% Aluminum Zinc Steel is the Future of Construction Materials

Introduction to Aluminum Zinc Steel in Construction

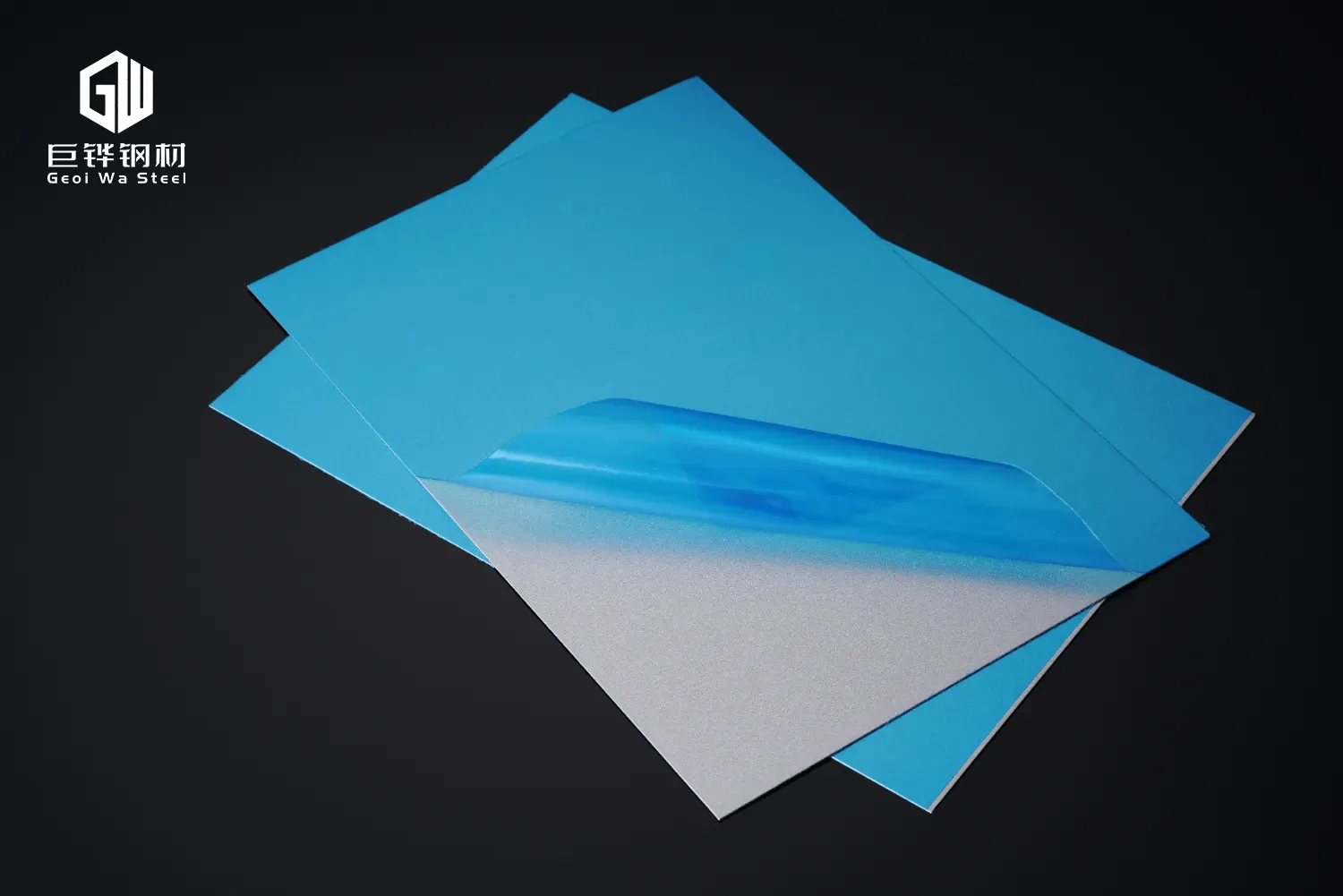

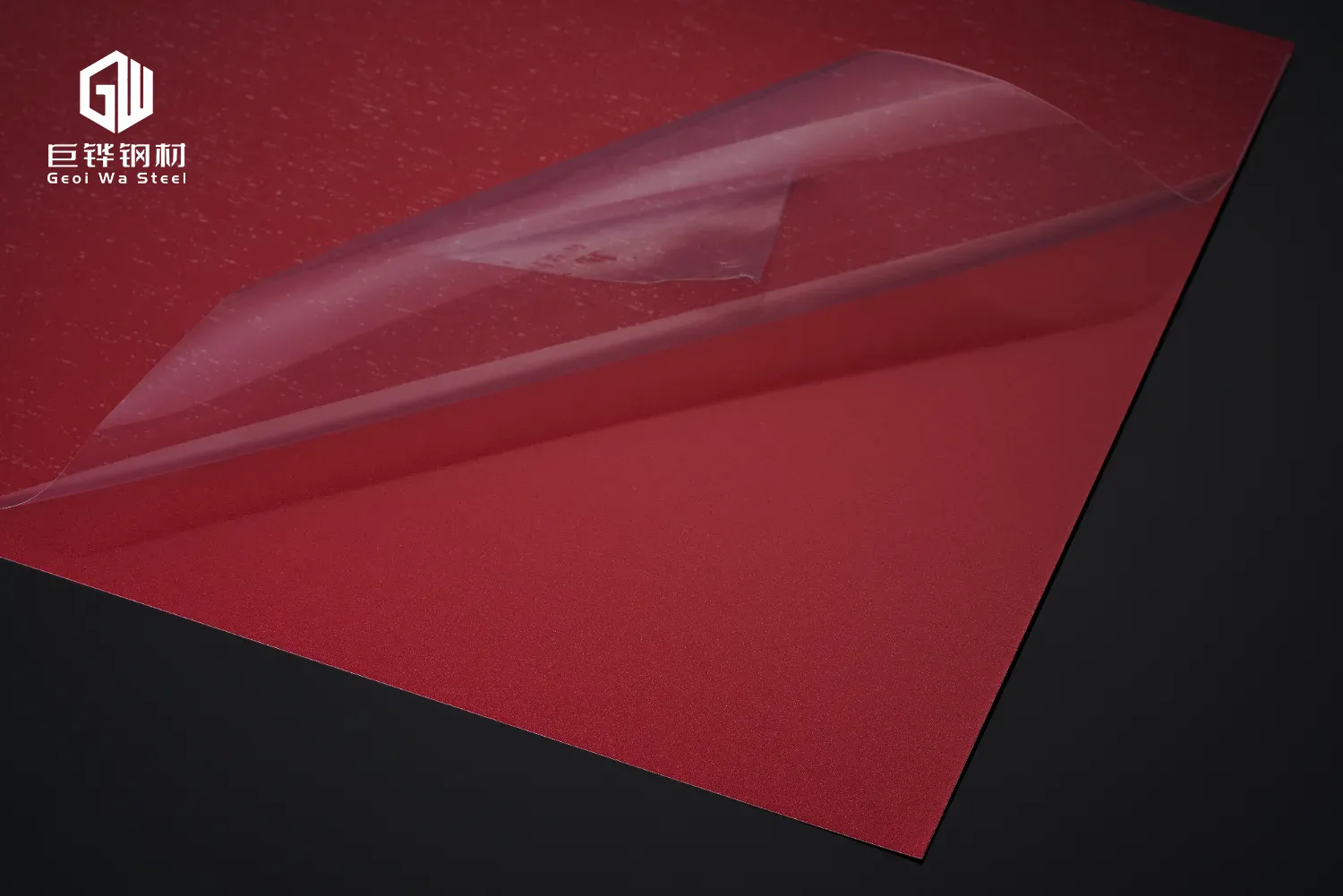

In the ever-evolving realm of construction materials, **55% aluminum zinc steel** has emerged as a revolutionary option that combines multiple benefits, setting the stage for a new era in building technology. Its unique composition, which includes a blend of aluminum, zinc, and steel, delivers exceptional performance features aimed at enhancing durability, sustainability, and overall construction efficiency. This article delves into the myriad advantages of **55% aluminum zinc steel**, exploring its future potential in construction.

Understanding the Composition of 55% Aluminum Zinc Steel

To fully appreciate the benefits of **55% aluminum zinc steel**, it is crucial to understand its composition. The alloy comprises approximately 55% aluminum, 43.4% zinc, and 1.6% silicon, resulting in a material that offers superior properties compared to traditional galvanized steel. The unique ratio of aluminum and zinc creates a protective layer that enhances corrosion resistance, significantly extending the lifespan of construction materials.

Key Properties of 55% Aluminum Zinc Steel

1. Exceptional Corrosion Resistance

One of the standout features of **55% aluminum zinc steel** is its remarkable resistance to corrosion. The aluminum component provides a protective barrier that prevents oxidation, while the zinc further enhances this protective layer, making it ideal for various environments, including coastal areas prone to saltwater exposure.

2. High Durability and Strength

This material not only resists corrosion but also offers high tensile strength. The steel content ensures that structures made from **55% aluminum zinc steel** can withstand heavy loads and harsh conditions, making it an excellent choice for both residential and commercial applications.

3. Lightweight Yet Robust

Despite its strength, **55% aluminum zinc steel** is relatively lightweight compared to other construction materials. This characteristic allows for easier handling, transportation, and installation, ultimately leading to reduced labor costs and improved efficiency on construction sites.

4. Thermal Reflectivity

The aluminum coating on this steel enhances thermal reflectivity, thereby contributing to energy efficiency in buildings. This property helps to reduce cooling costs in warmer climates by reflecting sunlight, making buildings more sustainable.

The Sustainability Aspect of 55% Aluminum Zinc Steel

As the construction industry increasingly prioritizes sustainability, **55% aluminum zinc steel** emerges as a leading choice. The production process of this material is more eco-friendly than traditional steel manufacturing methods, as it requires less energy and generates fewer emissions. Additionally, the longevity of **55% aluminum zinc steel** reduces the need for frequent replacements, thus minimizing waste.

Recyclability and Environmental Impact

Another significant advantage is its recyclability. At the end of its lifespan, **55% aluminum zinc steel** can be fully recycled without losing its structural integrity, contributing to a circular economy where materials are reused rather than discarded.

Applications of 55% Aluminum Zinc Steel in Construction

The versatility of **55% aluminum zinc steel** makes it ideal for a wide array of applications within the construction sector.

1. Roofing

Due to its corrosion resistance and reflective properties, **55% aluminum zinc steel** is commonly used in roofing applications. It provides longevity and reduces cooling costs in buildings, making it a preferred choice for both commercial and residential roofs.

2. Wall Cladding

The aesthetic appeal and durability of this material make it suitable for wall cladding. It can enhance the appearance of a structure while providing necessary protection against environmental elements.

3. Structural Components

Its high tensile strength allows **55% aluminum zinc steel** to be used in structural applications, including beams, columns, and supports. This material ensures the integrity and safety of buildings, making it a reliable choice for construction professionals.

Cost-Effectiveness of 55% Aluminum Zinc Steel

While the initial investment in **55% aluminum zinc steel** may be higher than traditional materials, the long-term cost savings are significant. The durability and low maintenance requirements of this steel lead to reduced operational costs over the lifespan of a building.

Lower Maintenance Costs

Buildings constructed with **55% aluminum zinc steel** require less frequent maintenance and repairs due to its corrosion resistance. This factor translates into lower maintenance costs, allowing property owners to allocate their budgets more efficiently.

Energy Efficiency Savings

The thermal reflectivity of **55% aluminum zinc steel** helps in reducing energy consumption for cooling. Over time, this energy efficiency translates into substantial savings on utility bills, enhancing the overall cost-effectiveness of using this material.

Industry Trends Favoring 55% Aluminum Zinc Steel

As construction practices evolve, several trends point towards the increased adoption of **55% aluminum zinc steel**.

1. Growing Demand for Sustainable Materials

With an increasing emphasis on sustainability, builders and architects are seeking materials that minimize environmental impact. **55% aluminum zinc steel** fits this criterion perfectly, aligning with modern construction goals.

2. Technological Advancements

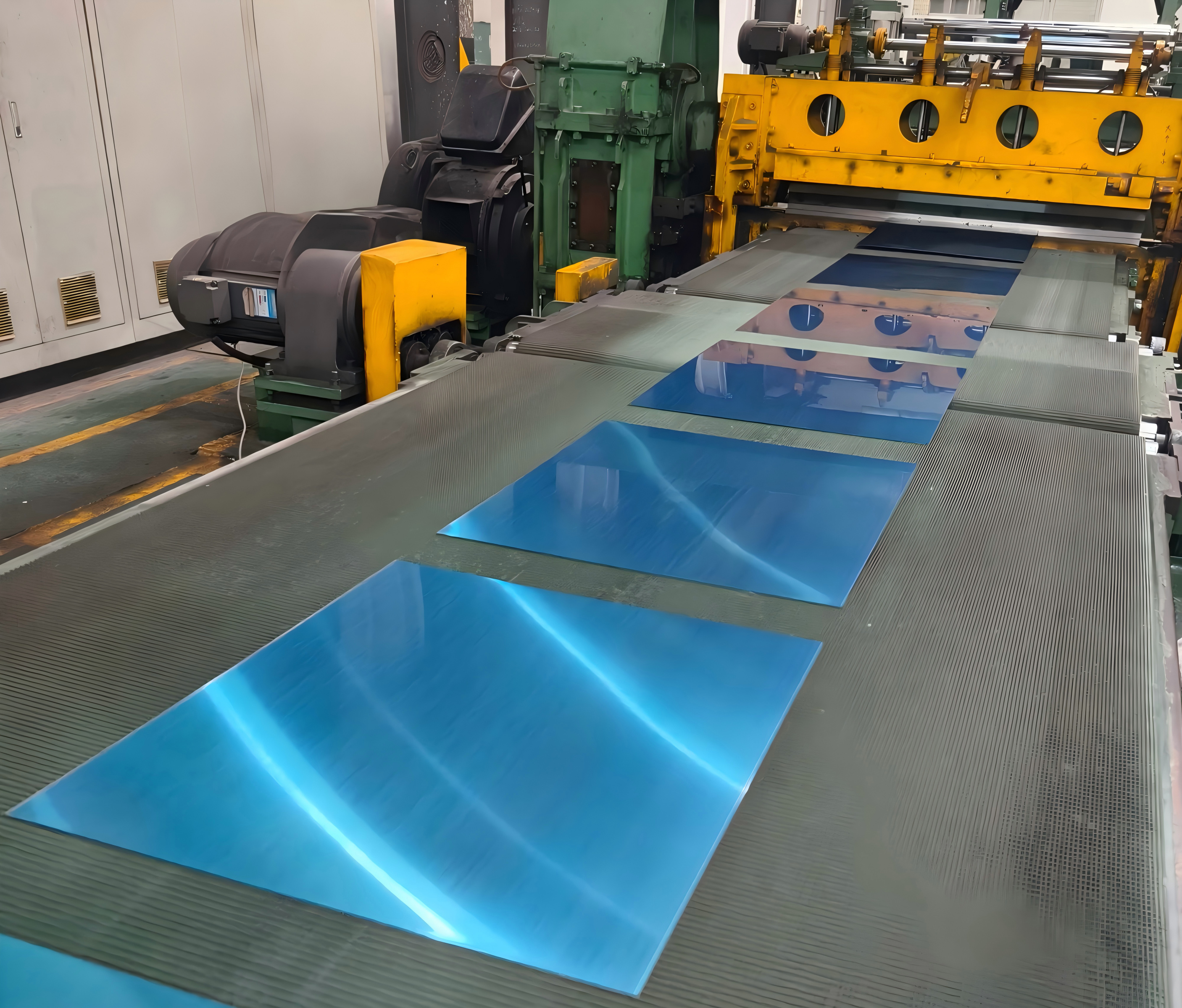

Advancements in manufacturing processes are making it easier and more cost-effective to produce **55% aluminum zinc steel**. As technology continues to improve, the availability and affordability of this material are expected to rise.

Comparing 55% Aluminum Zinc Steel with Other Materials

To understand its advantages fully, let's compare **55% aluminum zinc steel** with other commonly used building materials.

1. Traditional Galvanized Steel

While galvanized steel offers some corrosion resistance, **55% aluminum zinc steel** significantly outperforms it. The superior protective layer of aluminum and zinc leads to a longer lifespan and better performance in harsh environments.

2. Stainless Steel

Although stainless steel is known for its corrosion resistance, it is often more expensive and heavier than **55% aluminum zinc steel**. The latter offers similar benefits at a lower cost and weight, making it a more practical choice for many applications.

Challenges and Considerations

Despite its many advantages, there are challenges associated with the use of **55% aluminum zinc steel**. Understanding these challenges can help builders make informed decisions.

1. Initial Cost Concerns

The upfront cost can be a barrier for some projects. However, considering the material’s longevity and low maintenance needs can mitigate this concern over time.

2. Availability and Supply Issues

As demand for **55% aluminum zinc steel** increases, supply chains may face challenges in meeting needs efficiently. Builders should consider sourcing strategies to ensure timely access to this material.

Future Outlook for 55% Aluminum Zinc Steel

The future of **55% aluminum zinc steel** looks promising. As the construction industry continues to evolve towards sustainability and efficiency, materials like aluminum zinc steel will play an integral role.

1. Innovations in Material Science

Research and development in material science are likely to yield even more advanced formulations of aluminum zinc steel, further enhancing its properties and applications in construction.

2. Shifting Industry Standards

As building codes and regulations evolve to prioritize sustainability and efficiency, **55% aluminum zinc steel** will increasingly align with industry standards, positioning it as a go-to material for modern construction projects.

Conclusion

In conclusion, **55% aluminum zinc steel** is poised to revolutionize the construction industry with its unique combination of properties, including exceptional corrosion resistance, durability, and sustainability. Its versatility across various applications, coupled with long-term cost savings and energy efficiency, makes it a compelling choice for builders and architects alike. As we move forward, embracing this innovative material will not only enhance construction practices but also contribute to a more sustainable future for our built environment.

Frequently Asked Questions (FAQs)

1. What are the primary advantages of using 55% aluminum zinc steel in construction?

The primary advantages include exceptional corrosion resistance, high durability, lightweight properties, and energy efficiency through thermal reflectivity.

2. How does 55% aluminum zinc steel compare to galvanized steel?

**55% aluminum zinc steel** outperforms galvanized steel in terms of corrosion resistance and longevity, making it a superior choice for various applications.

3. Is 55% aluminum zinc steel environmentally friendly?

Yes, it is environmentally friendly due to its recyclability and lower energy production processes compared to traditional materials.

4. Can 55% aluminum zinc steel be used for roofing applications?

Absolutely! Its corrosion resistance and thermal reflective properties make it an excellent choice for roofing materials.

5. What is the cost-effectiveness of using 55% aluminum zinc steel?

While the initial investment may be higher, the long-term savings in maintenance and energy costs make it a cost-effective option overall.

Latest News

2025-10-17

Any Questions? Get In Touch.

We Can Recommend Suitable Products According To Your Needs.